Home | Mold Asset Management

Global Mold Management

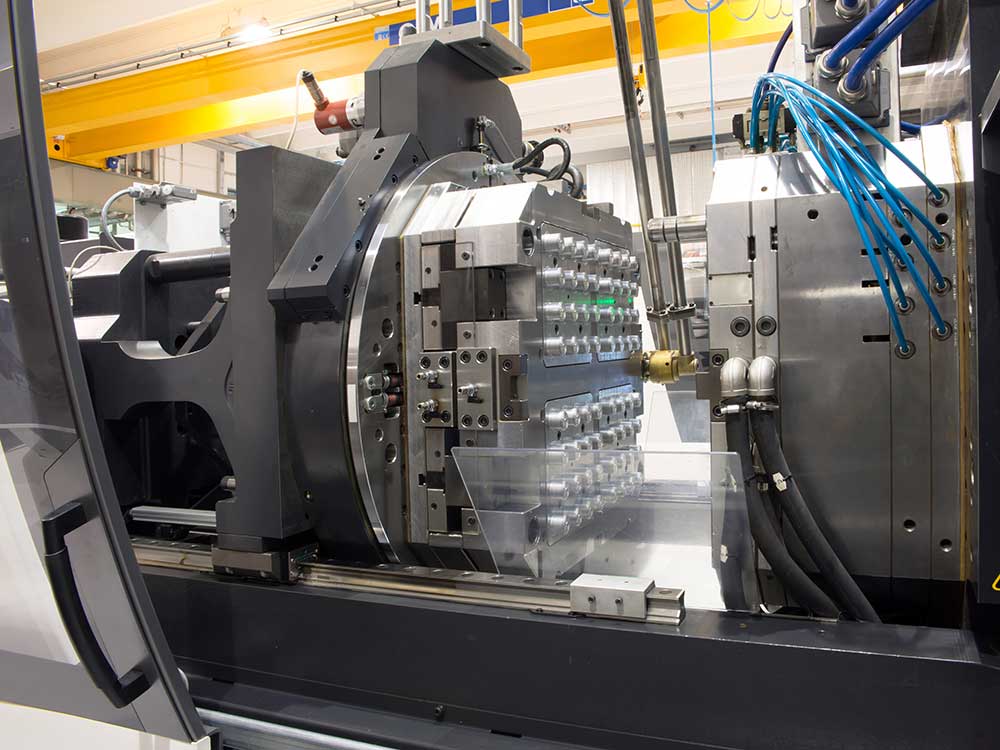

A unique, powerful, turnkey solution for manufacturers looking to gain control of their mold assets

A common challenge faced by original equipment manufacturers around the globe is finding a way to manage their mold assets. OEMs invest many millions of dollars in the development of molds used to manufacture their products and packaging but often overlook asset and tool life management. It’s not unusual for large companies to own thousands of molds, which can be located in multiple locations in different countries. And if they’re outsourcing any part of their manufacturing to third-party resources, it can become even more difficult to maintain inventory and control over these fixed assets.

At COAST, our single focus is to turn these mold management challenges into opportunities that reduce risk and strengthen core manufacturing operations. Our one-of-a-kind Global Mold Management program combines powerful cloud-based Asset Management Technology with expert support to help mold makers save time and money by not only tracking assets but maximizing their utilization.

By integrating a quality mold asset management program that focuses on people, process and technologies, companies can extend asset life, improve efficiency, reduce downtime, stabilize supply chains, reduce service hours, and improve their bottom line.

How do I know whether my company needs a global mold management program?

The integrity and reliability of physical assets plays a key role in helping companies compete in today’s fast-paced and competitive environment. The best organizations view asset management as a critical step to ensuring long-term success. And they are continuously seeking ways to keep pace with supply and demand while mitigating risk and minimizing costs. Think you’ve got things under control? Ask yourself these five important questions:

1. How many assets does your company have and what is their total value?

2. Do you know where all your assets are located?

3. What is the condition of each asset?

4. What is the cost to maintain the assets?

5. When should the assets be replaced?

COAST is here to make sure you can answer all of these questions at any moment – even if your company’s assets are located at multiple locations around the globe. We are uniquely positioned to help medium and large enterprise-level companies transform the way they manage and maintain their global assets to assure greater business continuity.

Now it’s your turn to ask us a question. Find out what we can do for your organization.

Customized, end-to-end services for all manufacturers that manufacture internally or use third-party resources

Whether your company produces its molded products in-house or uses an outside molding partner, COAST provides ONE SOURCE for scalable end-to-end services to optimize the life cycle of all your assets, wherever they are located. Our solutions can be tailored to address specific problems and needs while delivering significant and measurable value for everyone involved.

We work with multinational consumer packaged goods, medical device, pharmaceutical, industrial, and automotive manufacturers to create a better understanding of asset management, reach a consensus on manufacturing objectives, and prepare a customized plan for successful implementation.

Our ultimate goal is for companies to fully realize the concept of utilization. Once this occurs, they can predict and budget for the future since every tool has a lifespan. This is the COAST difference. Our complete Global Mold Management solution makes it possible for manufacturers to go forward with an elevated approach to manufacturing excellence.

COAST Global Mold Management Services

Dedicated Regional Support

With offices strategically located in the U.S., India, Brazil and Singapore, COAST’s team of experts supports clients in virtually every country on the globe.

Relationships Built on Trust

COAST understands the importance of existing business relationships and our entire staff adheres to the strictest levels of confidentiality. We are happy to abide by mutual non-disclosure agreements and we are very transparent about how our services deliver value to all parties involved. Through proactive communication and software utilization, it becomes a joint effort to improve overall efficiency.

Tooling Asset and Life Cycle Management

COAST can help your company develop and implement standardized maintenance management processes with complete data management that is fully supported by our Global Mold Management technology platform. This includes everything from asset utilization and history to work orders and current condition.

People-Focused Management

Leading companies are driven by people who are properly trained across relevant fields and who possess the skills needed to support an organization’s goals and help it grow. COAST supports its clients with a variety of engineering, technical project, qualification, business, and relationship management initiatives.

Supplier Onboarding and Management

COAST maintains relationships with tooling manufacturers around the globe who we evaluate based on the quality of their work, production capacity, transparency, and pricing models. In many regions, we are able to negotiate discounts based on the high volume of work we procure.

Procurement and Financial Management

COAST understands procurement exceptionally well and can manage the entire process from beginning to end. We obtain quotes that make the most sense from a work prioritization standpoint, initiate purchase orders, write capital request forms, and perform accurate budget forecasting based on the history, condition, and utilization of tools. Having one reliable source for procurement not only speeds the process but saves companies money by requiring fewer employees.

Mold Qualification and Validation

As plastic manufacturing experts, we can help you achieve the best molding processes while adhering to stringent qualification requirements for material testing, color testing, packaging requirements, in-process inspection, first article inspection, and more. Our highly-trained plastics engineering specialists can assist with analytical troubleshooting (ATS) while ensuring that your final product performs by using standardized process capability (Cp, CpK) and process performance (Pk, PpK) reporting methodologies.

Tooling Condition and Health Management

Whether at your location or at a third-party site, our team will physically inspect each asset and its corresponding parts. The assets are given a “grade” on a predetermined scale and their condition is entered into our software, along with specific recommendations that include everything from cleaning, sanding and welding to parts replacement. Using our software, users can initiate work orders, schedule maintenance activities, and watch the overall condition rating of their tools improve significantly. This results in a lower cost of ownership of your tools and a lower manufactured product cost since more cycles means more output.

Mold Replacement

From refurbishing to total replacement, we have resources in place to ensure molds are returned to like-new condition. Often times we can save companies the unnecessary expense of third-party markups on tools sent away for repair.

Spare Parts Inventory

Without a backup plan, tool failure can be catastrophic for time-sensitive products that are ordered as needed. COAST can help develop a streamlined process that will help your company avoid embarrassing or costly delays in the supply chain.

Staff Augmentation

From project management, mold and tooling program management, and package engineering to converter selection, process development and more, COAST provides onsite support as needed.

Mold Decommissioning

Retiring assets requires proper documentation and disposal. Let COAST reduce patent risk exposure and keep you in compliance by creating a standardized process that includes photo validation.

Key benefits of a quality Global Mold Management program

- Centralized management of global assets

- Asset condition transparency

- Optimized production capacity

- Standardized processes

- Minimized disruptions to supply chain

- Faster problem solving

- Decreased maintenance costs

- Decreased costs to maintain asset budgets

- Increased value of assets (extended life = more output)

- Forecasting and managed spending

- Predictive maintenance

- Greater accountability

- Reduced errors

- Automated inventory control

- Predictive maintenance

Are you a plastics mold manufacturer?

Leverage our strategic consulting expertise to help your company become as agile and profitable as possible.