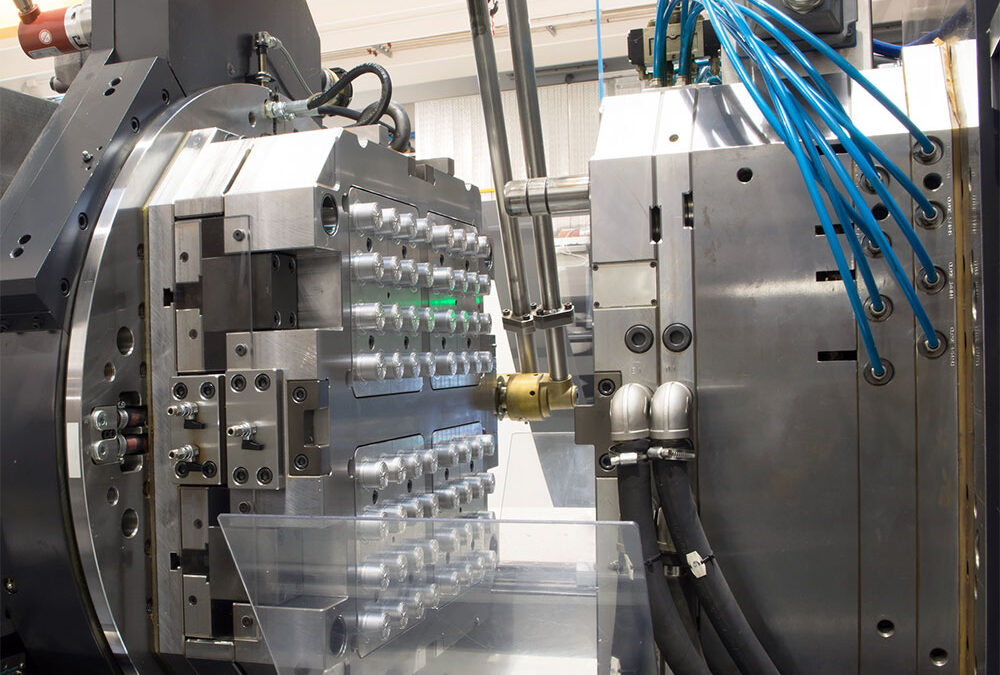

Plastic molding is a vital process in the manufacturing industry, but it also comes with its own set of challenges. One of the most important considerations for any plastic molding operation is the management of the molds themselves. Proper mold management is essential for the entire lifecycle of the mold, from design and development to maintenance and retirement.

The first step in effective mold management is the design and development of the mold itself. This includes ensuring that your product design is manufacturable, with the proper resin selection. Mold design begins with selecting the appropriate technologies and quantifying the number of cavities required to meet your demand requirements. Tool specification documents are used to define your quotation and technical tool requirements, including Class of Construction per SPI guidelines, proper tool steel grade. hardness, and coatings for the desired life cycle. Q thorough mold design review is critical for ensuring that the design is optimized for efficient and consistent production. It’s also important to consider the end-of-life plan for the mold, as some materials may be more difficult to recycle or dispose of than others.

Once the mold is in use, proper maintenance is key to ensuring its longevity and continued production efficiency. Your tooling supplier can provide guidance on maintenance scheduling and spare parts requirements to maintain your mold’s health. This includes regular cleaning and inspection, as well as the use of appropriate lubricants and release agents. It’s also important to keep accurate records of the mold’s usage and any repairs or maintenance that have been performed.

When a mold reaches the end of its useful life, it’s important to have a plan in place for its retirement. This may include repairing or refurbishing the mold for continued use, or recycling or disposing of it in an environmentally friendly, and confidentiality protected manner.

In conclusion, proper mold management is essential for the entire lifecycle of the mold, from design and development to maintenance and retirement. By considering the end-of-life plan for the mold, regular maintenance and keeping accurate records, manufacturers can ensure the longevity and efficiency of their plastic molding operations.

Click here to view or download the white paper.

Contributing author: Dave Jackson

Recent Comments